SINGULUS TECHNOLOGIES AG

Booth number: V6505

www.singulus.com/

About us

SINGULUS TECHNOLOGIES Thin-Film Coating and Surface Treatment

Address

Hanauer Landstr. 103, 63796 Kahl am Main

63796 Kahl am Main

Germany

E-mail: thomas.kuenzl@singulus.de

Phone: +49 176 203 50366

Internet: www.singulus.com/

429 D Hayden Station Road

CT-06095 Windsor

United States

E-mail: sales@singulus.com

Phone: +1 860 6838000

Internet: www.singulus.com/

Contact person:

Products & Services

We offer a comprehensive range of innovative products and solutions for advanced materials processing and solar cell manufacturing:

Perovskite Solutions

Vacuum Coating (PVD / PECVD)

Evaporation / Closed Space Sublimation (CSS)

Edge Passivation Deposition (EPD) / Passivated Edge Deposition (PET)

Semiconductor Process Equipment

Wet Processing

Lacquering

Turn-Key Solution

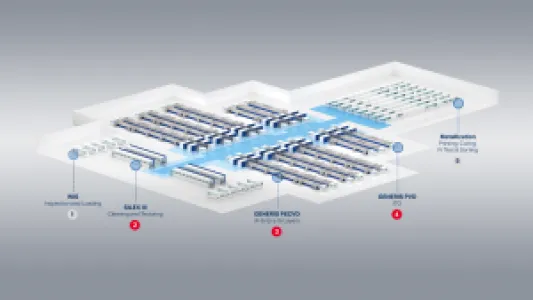

GENERIS PVD Inline Sputtering System

With the latest system generation GENERIS PVD, SINGULUS TECHNOLOGIES can assure capacities up to 8,000 wafers per hour of G12 HJT cells. There are further savings due to the smaller footprint of the equipment and related smaller building and cleanroom space requirements. The dual-sided processes of the GENERIS PVD require less wafer handling resulting in reduced wafer breakage, wafer damage and wafer marks. SINGULUS TECHNOLOGIES takes advantage of in-house engineering of crucial components such as sputtering magnetrons, simulation and optimization of different sputtering processes and processes developed using state-of-the-art sputtering lab equipment at SINGULUS TECHNOLOGIES R&D center. Newly developed processes can be directly industrialized to the GENERIS PVD mass production platform.

GENERIS PECVD Inline System for TOPCon, POLO, HJT & PERC Solar Cells

SINGULUS TECHNOLOGIES employs inductively coupled plasma (ICP) and capacitively coupled (CCP) sources for inline PECVD coating applications. ICP is a method that offers a high electron and activation density in conjunction with low ion energy, which allows very high deposition rates over a large width and extraordinary layer quality with wide process windows at low substrate damage. Therefore, ICP plasma sources are ideally suitable for high-rate and low-damage mass production of electronic devices like solar cells. CCP is an ideal method for depositing of thin or thick conductive layers, highly doped as needed in the PV cell technology. SINGULUS TECHNOLOGIES has developed new, large-scale linear plasma sources based on ICP and CCP technology. Both technologies are used for processes developed using state-of- the-art PECVD lab equipment at SINGULUS TECHNOLOGIES R&D center.

GENERIS PET for Passivated Edge Technology

Solar modules comprising cut cells are meanwhile part of the standard portfolio of almost every solar module manufacturer and supplier, with an increasing trend towards half cut/multi cut cells and shingle technology. The shingle technology uses solar cells not only being cut in half but also into multiple strips (3, 4 to 8). By dividing the cells, the electrical resistance of the metallization decreases, leading to a higher efficiency of the solar modules in comparison to the use of full cells, e.g., M10, G12. This even overcompensates Voc losses caused by damaged edges after cutting processes.

Modular Wet Processing System for Cleaning and Etching of High Performance Solar Cells

SINGULUS TECHNOLOGIES provides complete automated dry-in/dry-out solutions for wet-chemical treatments of Si-wafers in standard and high- efficiency solar cell lines. The recently introduced modular SILEX III batch system offers a wide range of process options. With respect to highest flexibility in configuration, the SILEX III is characterized by a clear modular design and compact footprint.

The SILEX III was specially designed for high production volumes. With this mass production system, which can achieve up to 730 MW annual capacity and more, depending on cell efficiency, all wet chemical applications (batch) at the HJT, TOPCon and PERC cell concepts can be covered. The SILEX III system achieves an output starting up to 14,000 wph (gross), depending on wafer size.

Turn-Key Solutions

SINGULUS TECHNOLOGIES is your full-solution provider for cell production lines — from initial design to mass production.

Our turnkey cell lines offer comprehensive packages that include cutting-edge equipment, advanced process technology, and high-level factory control systems. With SINGULUS TECHNOLOGIES, you benefit from maximum uptime, high throughput, and operational efficiency — enabling you to compete successfully with the industry’s leading players.

We bring in-depth expertise in key technologies such as PVD sputtering, PECVD, and wet processing, delivering reliable and high-performance equipment tailored to your production needs.

Horizontal Inline Vacuum Evaporation System

The EVARIS horizontal inline vacuum evaporation system is a cutting-edge solution designed for advanced thin-film deposition applications, utilizing proven thermal evaporation technology. The EVARIS system offers a highly optimized and flexible EVARIS Horizontal Inline Vacuum Evaporation System production platform, ideal for industries such as electronics, photovoltaics, and advanced coatings.

Inline Vacuum Evaporation & PVD Sputtering Systems

The inline evaporation tool is designed for the thermal evaporation of all perovskite-related precursor materials. It is specifically engineered for the deposition of high-quality perovskite layers, enabling the formation of optimized absorber structures for next-generation perovskite solar cells.

In addition to the evaporation system, SINGULUS offers production platforms with PVD sputtering modules for the deposition of functional layers such as electrodes, buffer layers, or barrier coatings. This combination enables a complete and flexible thin-film stack tailored to perovskite device architectures.

The system features a modular architecture, including a handling station, multiple heating and cooling zones, and dedicated deposition chambers. Leveraging proven thermal evaporation and PVD sputtering technologies, the tool ensures excellent material utilization, superior layer uniformity, and high reproducibility. Together with high uptime and mechanical yield, this results in an efficient, scalable, and future-ready production platform for perovskite solar cell manufacturing.

Close Spaced Sublimation (CSS)

Close Spaced Sublimation (CSS) is a critical process for cell manufacturing. This method involves sublimating the source material and depositing it onto a substrate placed in close proximity. The CSS technique offers significant advantages, such as high deposition rates, excellent film uniformity, and scalability for large-area module production. These factors make CSS a cost-effective and efficient solution for manufacturers aiming to meet increasing demand for e.g. CdTe solar modules.